×

The Standard e-Paper

Smart Minds Choose Us

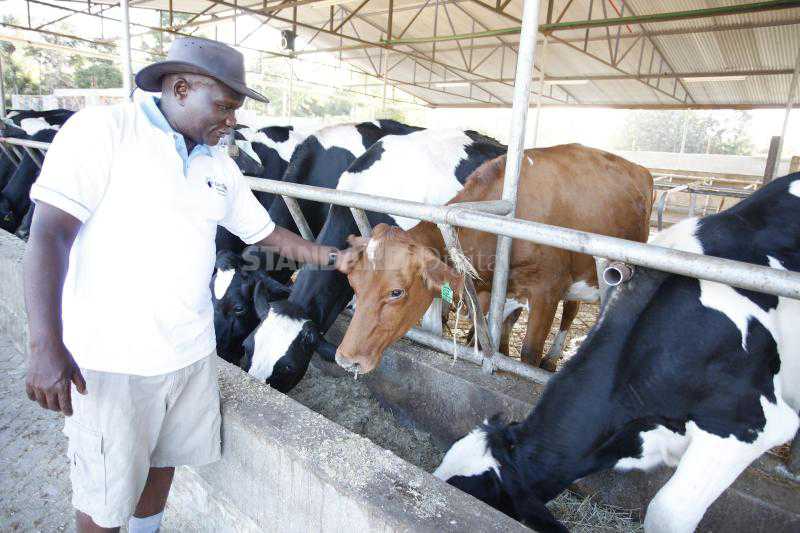

Fantastic. That is what best describes former South Mugirango MP Omingo Magara’s farm tucked deep inside Ongata Rongai. His one-acre farm is an example of how to run a modern-day dairy unit.

From the high investment in computerised milking machines, to the high standards of hygiene practised by the farmhands; everything spells Europe-style class.