×

The Standard e-Paper

Smart Minds Choose Us

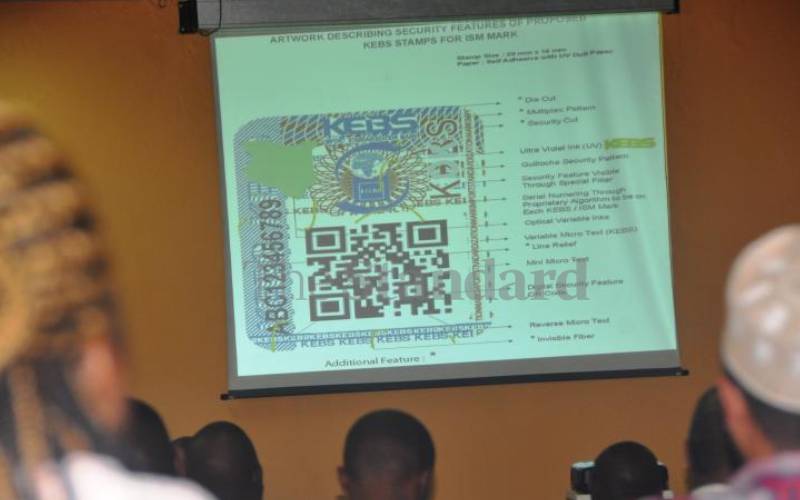

KEBS' standardization stamp. [Gideon Maundu, Standard]

Kenya Bureau of Standards (Kebs) has urged local manufacturers to ensure quality products that are safe and can effectively compete in the market.