×

The Standard e-Paper

Join Thousands Daily

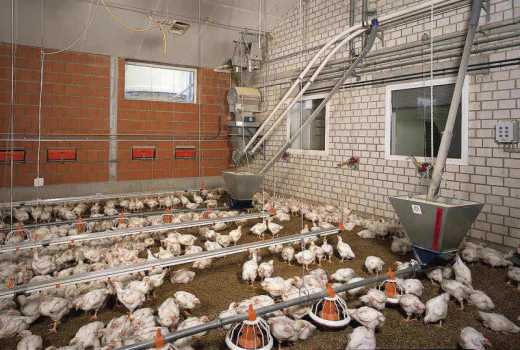

When you first step into the 25-acre Nereus Poultry farm, you will assume it is a factory of sorts because of the giant steel building.

Unless you are conversant with such a structure, from the outside you will see a facility with unique windows, giant ventilation spaces and beams.