×

The Standard e-Paper

Join Thousands Daily

If you want your farm to hit the next level, one of the magic ingredients is value addition. That is the thinking that transformed one farmer in Karuri, Gatundu North into a hotelier.

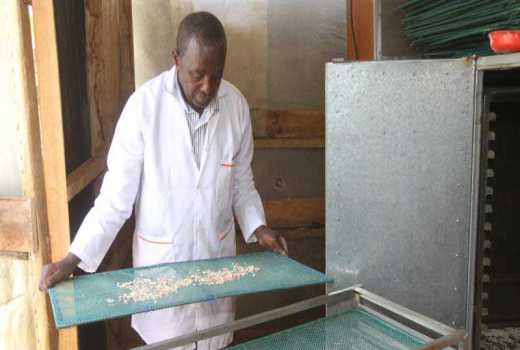

Smart Harvest starts this interview at the hotel to get first-hand look at the possibilities that come with adding value to fresh farm produce. We are at Bamboo Hotel, where the proprietor — Charles Mundia — a farmer-cum-hotelier, is taking us round.