×

The Standard e-Paper

Stay Informed, Even Offline

With the high prices of steel, vandalism of metals and rotting of timber, experts in the built environment are coming up with alternative building technologies that are cheap, durable and free from vandalism.

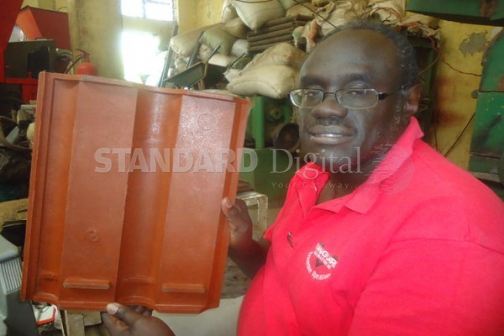

One such expert is Dr Aghan Oscar, who is recycling waste plastic into building materials and selling them to developers who use them to provide affordable housing.